Polymer, also known as plastic, consists of very large molecules formed by connecting hundreds of monomers together, creating long chains. The word polymer has its roots in Greek.

What is a Monomer ?

A Monomer is the smallest repeating unit of a polymer. For example, if we imagine a polymer as a chain, the individual links in the chain are the monomers.

What is Polymerization ?

It refers to the series of steps during which monomer molecules are linked together to form a large polymer molecule. Until a large polymer molecule is formed. Polymerization is the process of bonding monomers together through a series of chemical reactions.

Classification of different types of polymers.

Polymers can be categorized using various methods, with the most common ones described below. Additionally, polymers are divided into two main types based on their construction and usage: Engineering polymers and Commodity polymers, each of which is explained in separate sections.

A) Types of polymers based on their origin.

B) Types of polymers based on their response to heat.

C) Types of polymers based on chain structure.

D) Types of polymers based on crystallinity.

E) Types of polymers based on monomers.

F) Types of polymers based on application G) physical properties, as well as tacticity.

Classification based on origin.

Polymers are classified into three groups from a classification perspective: Natural, Synthetic, and Semi-Synthetic.

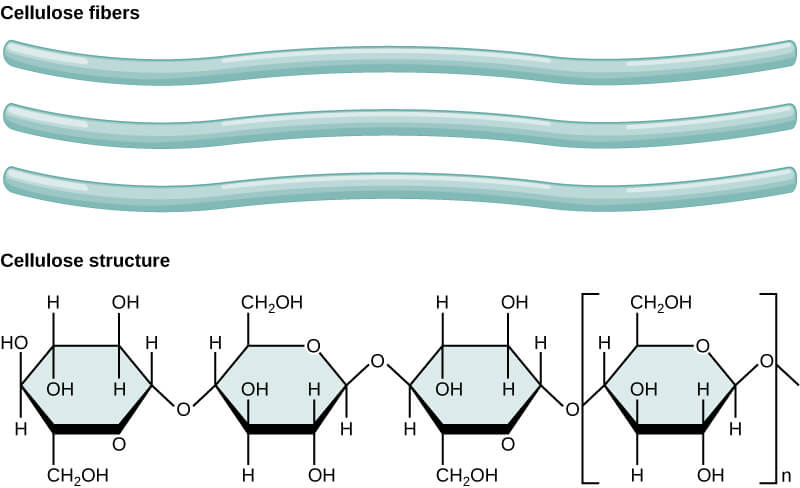

- Natural Polymers: These are polymers made solely from materials found in nature, such as wool, silk, natural rubber, cellulose, proteins, starch, and …

- Synthetic Polymers or Man-Made Polymers: These are polymers created in laboratories from low-molecular-weight molecules. Examples include nylons, polyethylene, polyester, synthetic rubbers, PVC, Teflon, and …

Semi-Synthetic Polymers: These polymers are produced by chemically modifying natural polymers to enhance their properties. Examples include cellulose acetate, cellulose nitrate, and …

Types of Polymers Based on Heat Behavior

Polymers are divided into two groups of Thrmoplastics and Thermosets in terms of their behavior against heat.

- ThermoplasticsThermoplastics, also known as heat-softening plastics, are polymers that can be easily molded into various shapes due to heat and then cooled to room temperature for use. They soften upon heating and become firm again upon cooling. Examples include polyethylene, PVC, polypropylene, polystyrene, and …

Thermoplastics consist of long chains, each of which may also have side groups or side chains. During the process and shaping, thermoplastics do not undergo any chemical reactions due to heat. Thermoplastics are flowable when exposed to heat and easily take the shape of different molds.

- Thermosets: or thermosetting polymers are hard and non-meltable polymers against heat. These polymers do not soften due to heat and do not have the possibility of remolding. Thermosets are polymers with cross-links that do not have the ability to be reused.

In thermoset resins, molecular active groups form crosslinks between molecules during the manufacturing process. These cross-links or the so-called curing of the material do not allow the material to soften due to heat. Thermoset materials are generally supplied as semi-polymerized compounds or liquid polymer-monomer mixtures so that production units can bring them into the final product shape and then bake them.

In other words, thermosets are baked by methods such as heat treatment or radiation and … The baking process is irreversible due to the same cross-links that were mentioned. That is, by reheating, unlike thermoplastics, these materials remain solid until they start to degrade. Some of the most important thermosets are phenolics, urea, melamine, epoxy, alkyds, polyesters,